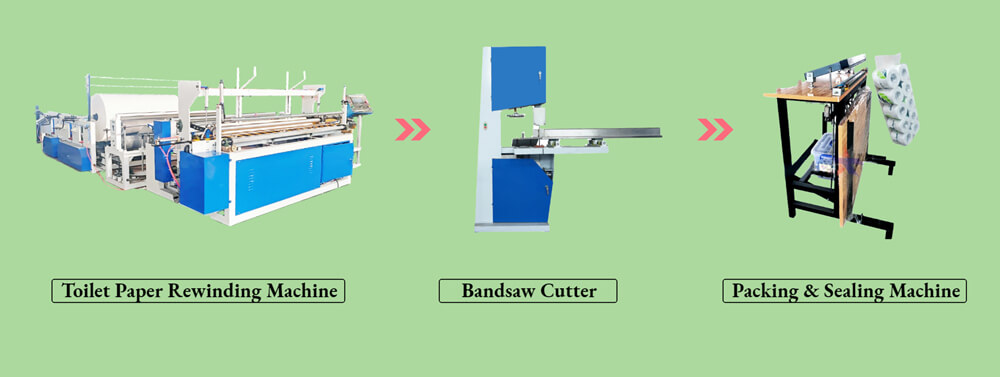

The small toilet paper roll making machine is used to produce small toilet tissue paper rolls from jumbo roll paper. The complete set toilet paper machine mainly inlcudes three machines: jumbo roll toilet paper rewinding machine, bandsaw cutter and packing machine. This semi automatic type toilet paper production line has the advantage of low investment and easy operataion. It is an ideal choice for beginners. The embossing pattern can be designed according to customers’ requirement.

If you need more information of this toilet paper machine, please contact us or send us inquiry!

Whatsapp/Mobile: 0086-13937183852

Email: andy@xingtumachine.com

1. Automatic log pusher after rewinding.

2. Automatic edge-trimming, glue spraying and sealing synchronously in one time. Leaving 10 - 18 mm paper tail, easy to rewind again, so reducing shortcut waste and save the cost.

3. Adopts advanced PLC programming controlling techniques, and man-machine interaction operation, date set and parameters fault shows on touch screen.

4. Adopts 2 pieces high precision spiral knife, low noise, clear perforation, adopt gearbox to have bigger range.

5. Three horizontal type back stands, pneumatic loading system, with wide driving flat belts, each jumbo roll can be adjusted independently.

6. Embossing device: Steel to wool paper roller.

| Machine Model | 1092 | 1575 | 2000 | 2200 | 2400 | 2600 | 2800 |

| Width of material jumbo roll (mm) | 1200 | 1800 | 2000 | 2200 | 2400 | 2600 | 2800 |

| Finished Products Diameter | Φ80~120mm (Tightness can be adjustable) | ||||||

| Finished Products Inner core Diameter | Φ32~60 mm | ||||||

| Material Jumbo roll diameter (mm) | Φ1200 (Other sizes please point out) | ||||||

| Jumbo Roll Inner core Diameter | Φ76.2 mm(other sizes please point out) | ||||||

| Perforation distance (mm) | 4 blade,90~160mm; 2 blade,180~320mm; | ||||||

| Production speed | 160-200 m/minute | ||||||

| Operation System | Touching-screen Multi-menu Man-machine Interface Operation System | ||||||

| Controller | PLC program | ||||||

| Mechanical driving | Driven by stepless regulator to guarantee the precise length of final products. | ||||||

| Air compressed system | 3HP air compressor, minimum pressure: 0.5Mpa | ||||||

| Power | 4kw-10kw (380V 50Hz) | ||||||

| optional items | |||||||

| Embossment | Single embossment, Double embossment, Edge embossment | ||||||

| Embossing system | 3 options: Paper roller to steel roller, rubber roller to steel roller, steel roller to steel roller | ||||||

| Jumbo roll stander | 1-3 plies | ||||||

| Rewinding unit | Core or coreless | ||||||

| Other special request for machine is welcome | |||||||